In the world of industrial equipment and fluid transfer systems, efficiency, durability, and ease of use are paramount. One component that stands out in meeting these requirements is the Aluminum Camlock Coupling. This versatile and robust coupling system has become a staple in various industries due to its reliability and simplicity. In this blog, we’ll delve into what an Aluminum Camlock Coupling is, its key features, and its wide range of applications.

What is an Aluminum Camlock Coupling?

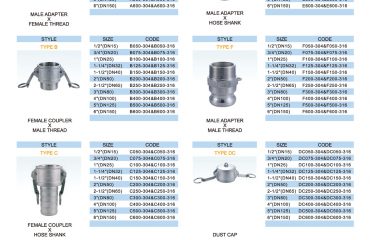

An Aluminum Camlock Coupling is a type of quick-connect coupling used to join hoses, pipes, or tubes in fluid transfer systems. It is designed for rapid connection and disconnection without the need for specialized tools. The coupling consists of two main parts: the male adapter (also known as the plug) and the female adapter (also known as the socket). The connection is secured by rotating the cam arms (or levers) on the female adapter, which lock the male adapter in place, creating a tight and leak-proof seal.

Aluminum Camlock Couplings are made from lightweight yet durable aluminum alloy, making them resistant to corrosion and suitable for use in various environments. They are available in different sizes and types (e.g., Type A, B, C, D, etc.) to accommodate a wide range of hose diameters and connection requirements.

Key Features of Aluminum Camlock Couplings

Lightweight and Durable: Aluminum construction ensures the couplings are easy to handle while being strong enough to withstand harsh conditions.

Corrosion-Resistant: Aluminum’s natural resistance to rust and corrosion makes these couplings ideal for use in wet or corrosive environments.

Quick and Easy to Use: The camlock mechanism allows for fast connections and disconnections, saving time and labor.

Versatile: Available in various types and sizes, Aluminum Camlock Couplings can be used in a wide range of applications.

Leak-Proof: The secure locking mechanism ensures a tight seal, preventing leaks and spills.

Applications of Aluminum Camlock Couplings

Aluminum Camlock Couplings are widely used across industries due to their versatility and reliability. Here are some of the most common applications:

Agriculture: In irrigation systems, these couplings are used to connect hoses and pipes for water transfer. Their quick-connect design makes them ideal for frequent assembly and disassembly.

Construction: Camlock couplings are used to transfer water, slurry, and other fluids on construction sites. Their durability ensures they can withstand rough handling and harsh conditions.

Chemical Industry: Aluminum Camlock Couplings are used to transfer chemicals and other fluids. However, it’s important to ensure the material is compatible with the specific chemicals being handled.

Oil and Gas: In the oil and gas industry, these couplings are used for transferring fuels, oils, and other liquids. Their leak-proof design ensures safe and efficient operations.

Food and Beverage: Aluminum Camlock Couplings are used in the food and beverage industry for transferring liquids like water, milk, and juices. They are easy to clean and maintain, making them suitable for hygienic applications.

Firefighting: Firefighters use these couplings to quickly connect hoses and equipment, ensuring a rapid response during emergencies.

Marine Industry: Due to their corrosion resistance, Aluminum Camlock Couplings are ideal for use in marine environments, such as transferring water or fuel on ships.

Advantages of Using Aluminum Camlock Couplings

Time-Saving: The quick-connect design reduces downtime during setup and disassembly.

Cost-Effective: Their durability and long lifespan make them a cost-effective solution for fluid transfer needs.

Interchangeability: Standardized sizes and types ensure compatibility with equipment from different manufacturers.

Low Maintenance: Aluminum’s resistance to corrosion and wear minimizes the need for frequent maintenance.